Mechanical draught (forced draught is subtype of mechanical draught)

The draught required in high capacity modern steam power plant may vary form 30 to 350 mm of water in order to maintain flow of large volume of air and gases (4×105 to 8 x105 m3/min). Also, large steam power plant is equipped with economizer and air preheater, the exit temperature of flue gases is sufficiently reduced. In such case in order to produce certain amount of draught the height of chimney may be high enough. It has been seen that draught produced by chimney hardly 10 to 20 mm of water. Also, it has effected by atmospheric conditions, no flexibility, poor efficiency and loss of energy.

It is not possible to produce a draught more than 40 mm water with the help of natural draught system (chimney) because it is neither economical nor convenient to build a chimney of enough height for larger amount of draught. Therefore, it becomes necessary to provide mechanical means to meet the larger draught requirements.

This mechanical arrangement used to produce larger draught is called artificial or mechanical draught which independent on climate conditions and flexible to meet fluctuating load on boiler. Boiler with mechanical draught do not need so high a chimney is necessary with natural draught. Chimney is needed in mechanical draught some avoid the smoke, dust, cinder and ash from falling over the adjacent buildings. The mechanical draught is created by fan,

There are three types of mechanical draughts as Forced draught, Induced draught and Balanced draught.

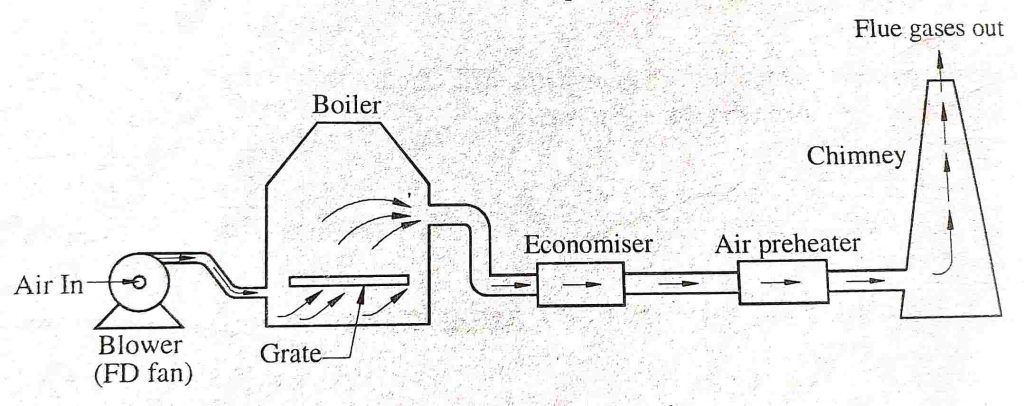

Forced draught

In a forced draught system, the pressure over boiler settings is normally maintained above atmospheric pressure. Therefore, this draught is also known as positive draught. In this diagram, a blower/tan is installed near the base of the boiler as shown in Fig. and air is forced to pass through the furnace, flues, economizer, air-preheater and to the stack or chimney. A stack/chimney in this draught system required to discharge gases high in the atmosphere to prevent the contamination. It is not much significant for producing draught therefore height of the chimney may not be very high.

Forced draught is commonly used with under feed stokers, as considerable pressure is needed to force the air required for combustion up through the deep fuel bed.

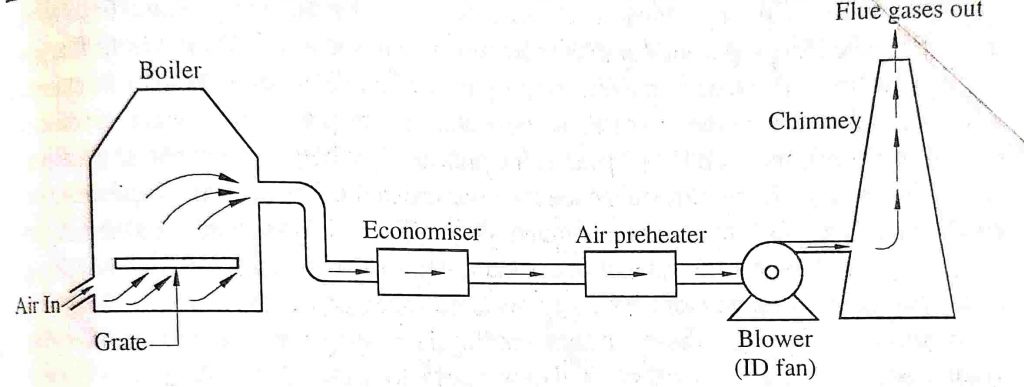

Induced draught

In an induced draught system, the pressure over the fuel bed is maintained below the atmosphere. The blower or fan is installed near or at base of the chimney as shown in Fig. and sucks the burned gases from the furnace. Hence pressure inside the furnace is reduced below atmosphere and induces the atmospheric air to flow through the furnace. The action of the induced draught is similar to the action of the chimney. But draught produced by induced draught system is independent of the temperature of the hot gases therefore the flue gases may be discharged as cold as possible in economizer and air preheater.

Induced draught is used generally when economizer and air preheater are incorporated in the system. The induced draught fan or blower should be placed such that the temperature of gas handled is lowest possible. This clearly suggests that it should be installed after the air preheater. In an induced draught system, fan deals with hot flue gases hence it has to handles large volume of hot gases. Therefore, size of induced draught fan and power required are more compared to forced draught fan.

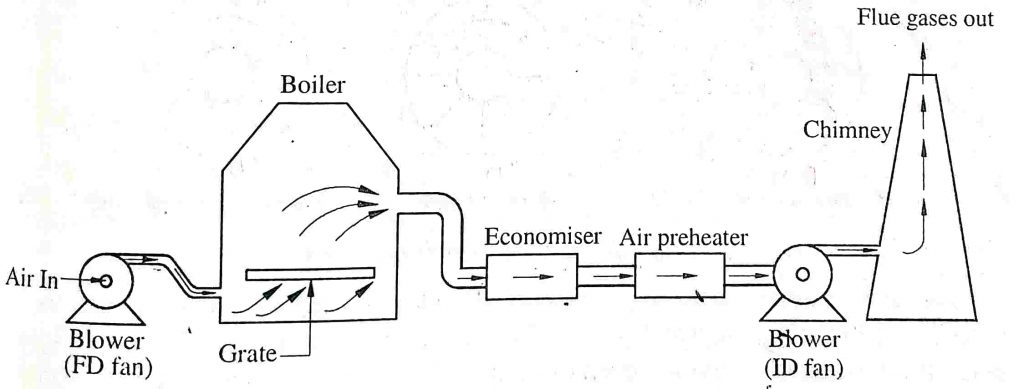

Balanced draught

The balanced draught is a combination of forced, induced draught and chimney. In this system the forced fan is located at base of boiler and induced fan is located at base of chimney as shown in Fig. Air is push by forced fan and flue gases is sucked by induced fan As we know that the forced draught system the pressure inside furnace is above atmosphere. It forced draught is used alone, then furnace can not be opened either for firing or inspection because the high pressure air inside the furnace will try to blow out suddenly. therefore, there is chance of blowing out the fire completely and furnace stops. Similarly if the induced draught is used alone, then also furnace can not be opened either for firing or inspection because the cold air will try to rich into the furnace as the pressure inside the furnace is below the atmospheric pressure. This reduces the effectiveness of draught and dilutes the combustion. The balanced draught overcomes both the difficulties as above either using forced draught or induced draught alone.

In the balanced draught, the forced fan supplies air at a sufficient pressure tor air to pass through fuel bed for proper and complete combustion. The induced fan removes the the flue chimney gases them through the boiler flues, economizer, and air preheater and then sends them to the chimney. The forced fan maintains the pressure just above atmospheric pressure to overcomes resistance of fuel bed while induced fan maintains the pressure just below atmosphere removes hot gases from furnace, hence the pressure in the furnace will be in equilibrium. therefore, in a balanced draught system the forced fan overcomes the resistance in the air preheater (inside) and fuel bed (stoker) while the induced fan overcomes draught losses through the bed, economizer, air preheater (outside) and flues

Comparison / difference between forced draught and induced draught

| Forced draught | Induced draught |

| (1) Fan is installed near or at the base of the boiler (2) It handles low temperature and less volume of air, hence size and power required for forced fan is less than induced fan. (3) Fan handles air and thus water cooled beaning is not required (4) The pressure inside the furnace is above the atmospheric pressure, hence there is no chance of air leakage. However, when doors are opened for firing or inspection the high pressure air inside the furnace will try to blow out suddenly. (5) There is uniform-flow of air through the grate and furnace (6) The heat transfer efficiency will be higher than induced draught (7) Lower investment and operating costs Compared to induced draught. | (1) Fan is installed at base of chimney (2) It handles more volume of gases at higher temperature. Therefore, size and power required for induced fan is more than forced fan. (3) Fan handles flue gases of high temperature and thus water cooled bearings are needed for induced draught fan. (4) The pressure inside the furnace is below the atmospheric pressure, hence there is continuous air leakage is possible. (5) Flow of air is not uniform (6) The heat transfer efficiency will be lower than forced draught. (7) Higher investment and operating cost compared to forced draught |

Q1. Explain balanced draught.

Q2. What is location of fan in forced draught and induced draught in draught system?

Q3. Give difference/comparison between forced draught and induced draught.