Boyle’s Law – Definition, Equation, Examples, Calculator & FAQs

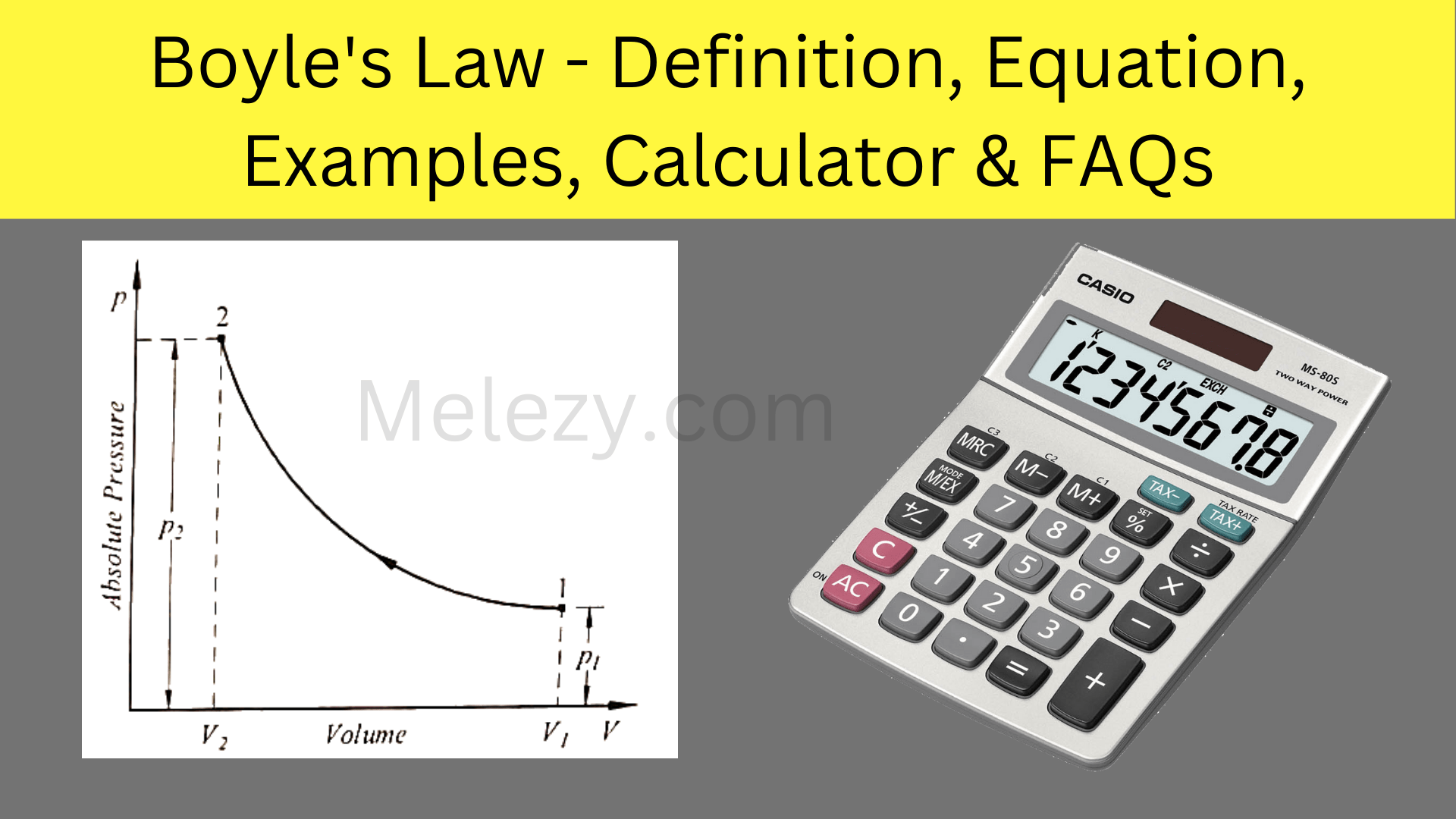

Boyle’s Law is a fundamental principle in physics that describes the relationship between the volume and pressure of a gas at a constant temperature. It was named after the Irish scientist Robert Boyle, who discovered the law in 1662. This article will explain Boyle’s Law, its equation, and provide some examples to help readers understand … Read more