Why and where it is used?

Bag filter is used where the dust products like bed material in power plant, lime powder, cement, big floor mill wastage, etc. powder products used as a output or input material. This bag filter is attached on the upper portion of the bunker of the material.

And if we are not using bag filter than below problem can be occurred in the industry or in the atmosphere.

- Material bunker is pressurized because the power material is conveyed in bunker via pressure of the air so all air will be collected in the bunker that can blast the bunker or make cracks on it.

- That bunker may take shape like a parabolic shape.

- All duct particles will be spread in the atmosphere from the vent of the bunker and that will cause health issue around the industry.

- The men power may refuse to work around that bunker due to the dust problem.

- It will cause daily cleaning problem also. Zero floor have daily much more material that will increase the cleaning cost.

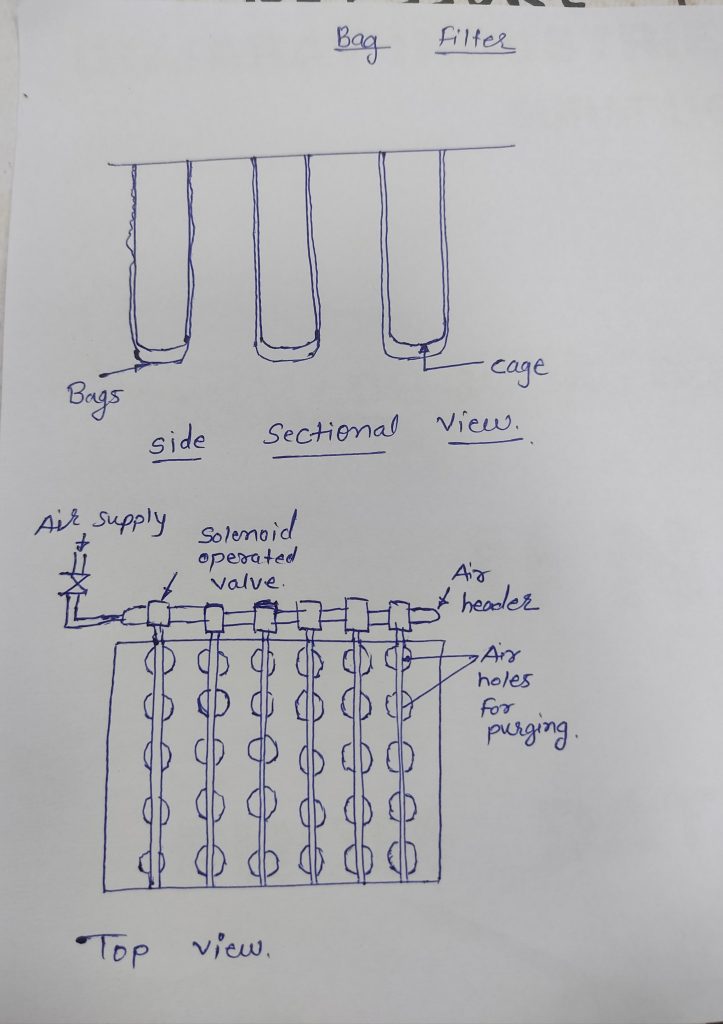

Construction of bag filter

It is rectangular block which bottom is open to the bunker and top has circle holes for fixing the bag with the cage. first, bag will be fixed on the case then bag and cage assembly will be fixed into the round circles of the filter. To close the top of filter completely, there are another doors on the top.

The purging air lines are completely above the row of the bag. we make a small hole just above the particular bag filters. that means a hole is drilled above all particular cage and filter assembly. air line is used for purge the air in cage of the filters for cleaning purpose. that air line is operated via number of SOV(solenoid operated valve) that can be operate manually or by automated system. Operation Timings of valves are set by C&I department as per the requirement.

Bag materials include nylon, polypropylene, polyester, porous PTFE film and other fluoropolymers, viscose, aromatic polyamides, felts and woven wool. The development of seamless bags in these various materials has helped to maintain the popularity and ubiquity of liquid bag filters.

One simple vent is given on top of the filter for air venting in the atmosphere.

Operation and Working of bag filter

Bunkers material is filled with help of air pressure during fill up dust is produce and stick on the bag. That dust will make layer on bag after some time then bunker will start to pressurized because air can’t be passed from layer of dust on bag. So after some pressure the pneumatic valve will be operated by the operation department one by one. So air will be passed from upper side of bag towards to bunker, all dust will be fall in the bunker. Dustless air will be passed in the atmosphere in the smooth operation. If the some bag got punctured due to some reason top of the bag filter will full of dust and dust will be vent into the atmosphere.