Natural draught function

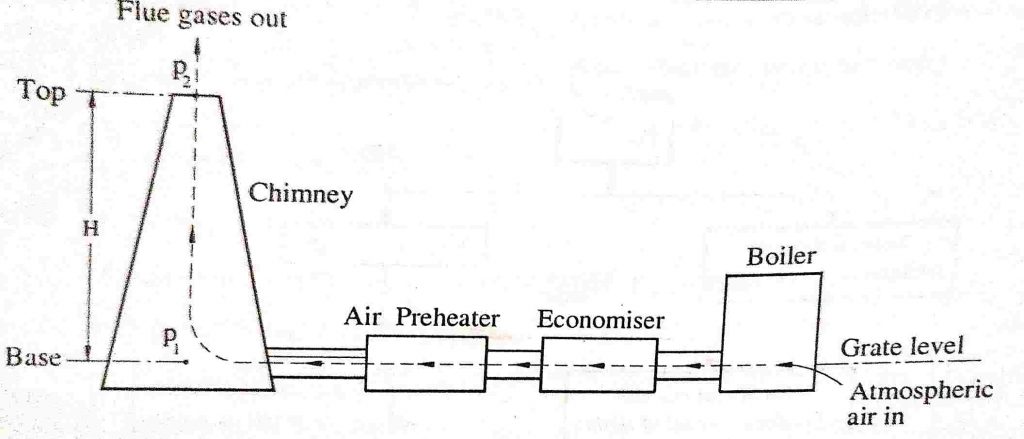

The natural draught is obtained by the use of chimney. The chimney in the power plant performs the following two functions.

(i) It produces draught (create pressure difference) which required to force air and gases through the furnace, boiler accessories and settings.

(ii) It comes the product of combustion to such a height that they will not be objectionable or injurious to surrounding.

The chimney is vertical tabular structure build either of masonary, concrete or steel. The draught produces by the chimney is due to density difference between the column of hot gases inside the chimney and cold air outside the chimney and also on the height of the chimney above the level of the furnace grate. The density difference depends on the temperature of flue gases passing in chimney and temperature of atmospheric air.

Advantages of chimney or natural draught:

(1) Chimney draught does not require any external power to produce draught.

(2) Simple in construction, less cost and has long life.

(3) Non-mechanical parts and hence maintenance cost is negligible.

(4) Chimney keeps flue gases at a high place in the atmosphere which prevents the contamination of atmosphere and maintains the cleanliness.

Disadvantages / Limitations of chimney or natural draught:

(1) The draught produced by chimney depends on height of chimney, atmosphere air temperature and temperature of flue gases leaving through the chimney. Hence, in order to get appropriate draught at given height of chimney, the flue gases have to be discharged at comparatively high temperatures resulting in the reduction in overall efficiency of plant. About 20% of heat released by the fuel is lost to the flue gases, otherwise it may be used to heat the feed water and air which is supplied to boiler.

(2) The maximum pressure available for producing natural draught by chimney is hardly 10 to 20 mm of water. Hence it is only used for very small boilers.

(3) Draught created by chimney is dependent on atmospheric air and flue gases conditions, hence there is no flexibility to create more draught under peak load conditions because draught available is constant for given height of chimney. The draught can be increased by allowing the flue gases to leave the chimney at higher temperature. This reduces the thermal efficiency of the plant.

(4) Due to low velocity of air, the mixing process of air and fuel is not proper and hence combustion is very poor. This increases the specific fuel combustion of boiler.

(5) In case of modem power plant, the draught produced by chimney is insufficient for high generating capacity and also reduces thermal efficiency. Therefore, now a days chimney is used with artificial draught system in all power plant only to discharge the flue gases high in the atmosphere to maintain the cleanliness of atmospheric air.

For numerical derivation part, you can refer power plant engineering by P.K. Nag (Mc Graw Hill) book.

Q1. State functions of natural draught

Q2. What are advantages and disadvantages/limitations of natural/chimney draught?