Dehydrogenation Heat Treatment (DHT) or Post-heating

Dehydrogenation Heat Treatment (DHT) is a treatment utilised specifically when welding or preheat is paused or stopped during the fabrication cycle or PWHT is not done immediately due to further fabrication requirements. It is usually done at 300-350 °C [600 – 650˚F (min 570 ˚F)]. Very common and used in place of Intermediate stress relieving (ISR). It is to ensure that trapped hydrogen in the welds has a chance to escape into the atmosphere. It is intended for welds that are less constrained, such as main reactor seams.

Reasons / Why Post-heating or Dehydrogenation Heat Treatment (DHT) is required?

Flux based processes like FCAW, SAW, SMAW introduces detrimental hydrogen in weld metal, which can lead to cold cracking.

It involves giving heat, but only to diffuse out hydrogen. Therefore it can’t be called “PWHT” or “postweld heat treatment” which is more used for microstructural changes, stress relieving, normalizing, tempering.

Therefore, DHT allows Hydrogen to diffuse out (higher diffusivity at high temp) from weldment and reduce chance of Hydrogen cracking or delayed cracking.

When to perform Dehydrogenation Heat Treatment (DHT)

Welds should be performed DHT if preheat is not to be maintained until PWHT and if ISR is not to be conducted. DHT shall be performed at minimum 300°C for a duration of one hour minimum.

Exact temperature and time depend on fabrication code and mutual understanding between fabricator and manufacturer. It sometimes may not be mentioned in standard but is used as recommended practice for some materials.

Post-heating is also appropriate where a partially filled weld cross-section is to be cooled.

Example:

API RP934-A (2.25 to 3 Cr steels) indicates that the DHT shall be performed at a minimum metal temperature of 300˚ C (570 ˚ F) for conventional steels and 350 ˚ C (660 ˚ F) for advanced steels when approved by purchaser. The duration should be agreed upon between manufacturer and purchaser; however, in no case should the duration be less than 1 hour for conventional steels and 4 hours for advanced steels. For tack welds, DHT can be reduced to preheat temperatures, for a minimum 1 hour.

ASME BPVC Sec-IX addresses DHT as post-heating which states holding a completed or partially completed weld at elevated temperature below 800°F (425°C) for the purpose of allowing hydrogen diffusion from the weld. (Ref-Definitions in ASME Sec IX)

Which materials and type of welds require Dehydrogenation Heat Treatment (DHT) ?

- Required mainly for Low Alloy Steel (e.g. Cr-Mo, Cr-Mo-V steel) and Q&T steel

- DHT is commonly allowed for conventional steels on non-restrained welds such as shell welds and shell-to-head welds

- It is utilised for welds that are less constrained, such as main reactor seams.

Factors to be considered when to use Dehydrogenation Heat Treatment (DHT)

- Degree of weld restraint

- Weld joint thickness

- Experience of the manufacturer

- Type of steel

One important thing to note, Although a DHT will remove hydrogen, it will not sufficiently restore toughness, especially for advanced materials which remain very brittle during pre-PWHT handling

For highly restrained joint and higher thicknesses, DHT is replaced by an Intermediate Stress Relieving (ISR) at 620-660°C /2-4hrs

How heating is carried out in DHT ?

- Involves heating provided by Oxy fuel flame or electric resistant coil method

- It should be heated from opposite side of welding wherever possible

- Temperature should be checked by thermo chalks (temperature sticks) during the period, or by IR temperature gun

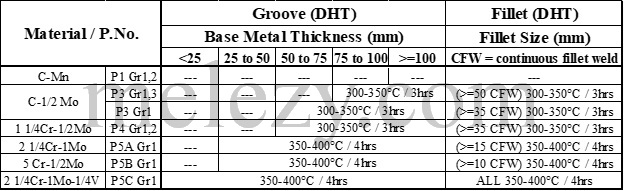

Dehydrogenation Heat Treatment (DHT) requirements for some Cr-Mo-V steels, thickness, type of weld

Summary of Dehydrogenation Heat Treatment (DHT)

- Also known as post heating

- Holding at 300-400°C for 2-6 hrs after welding and before cooling down to room temperature

- Allows Hydrogen to diffuse out (higher diffusivity at high temp) from weldment and reduce chance of Hydrogen cracking or delayed cracking

- Required for specific steels only

Outgassing or hydrogen bake-out (used in repair work of part in service)

It is related process to diffuse hydrogen out but used usually during repair or modification of a component which has seen service in a hydrogen environment, to reduce the hydrogen that has been introduced in service, before attempting to weld the component

Outgassing, also known as baking, is a preliminary procedure performed on operating plant that has been exposed to hydrogen-bearing chemicals while in service and is undergoing weld repair or modification. The goal of this treatment is to raise the temperature of the fabrication and hold it there, allowing hydrogen to diffuse out before welding and thereby reducing crack susceptibility.

Temperature and hold times vary depending on steel classification and section thickness, with temperatures up to 450°C and hold lengths ranging from 1 to 48 hours. The greater the temperature, the shorter the soak time. These temperatures and times will not be sufficient to change the microstructure or residual stress state.

Electrical resistance heating, as used for localised heat treatments, is the most common method, with thermocouples used to monitor and regulate the operation. To offer the essential reassurance and record that the cycle has been completed, a time temperature chart is created.

Difference between DHT (post-heating) and hydrogen bakeout (outgassing) – DHT vs hydrogen backout

| Dehydrogenation Heat Treatment – DHT (post-heating) | Hydrogen Bakeout (outgassing) |

| Diffuse out detrimental hydrogen during fabrication | Diffuse out detrimental hydrogen for repair or modification of a component which is in service in hydrogen environment |

| Soaking times are generally 1-6 hrs | Soaking times can be higher 1-48 hrs |

| Done just after welding | Done before welding |

References

- What is Post heating by TWI

- Jung-Chul (Thomas) Eun, “Handbook of Engineering Practice of Materials and Corrosion”, Springer 2020

- BS EN 1011-2

- API Recommended Practice 934-A, 3rd Edition 2019

- Dennis R. Moss, “Pressure Vessel Design Manual”, Elsevier 2012

- D Croft, “Heat Treatment of Welded Steel Structures”, Woodhead Publishing in welding, Elsevier, 1996

Good Article