Post Weld Heat Treatment PWHT

Post Weld Heat Treatment PWHT is a controlled process in which a welded material is reheated to a given temperature, kept at that temperature for a specified amount of time, and then cooled at specific rates to achieve the following objectives…..

Stress Relieving

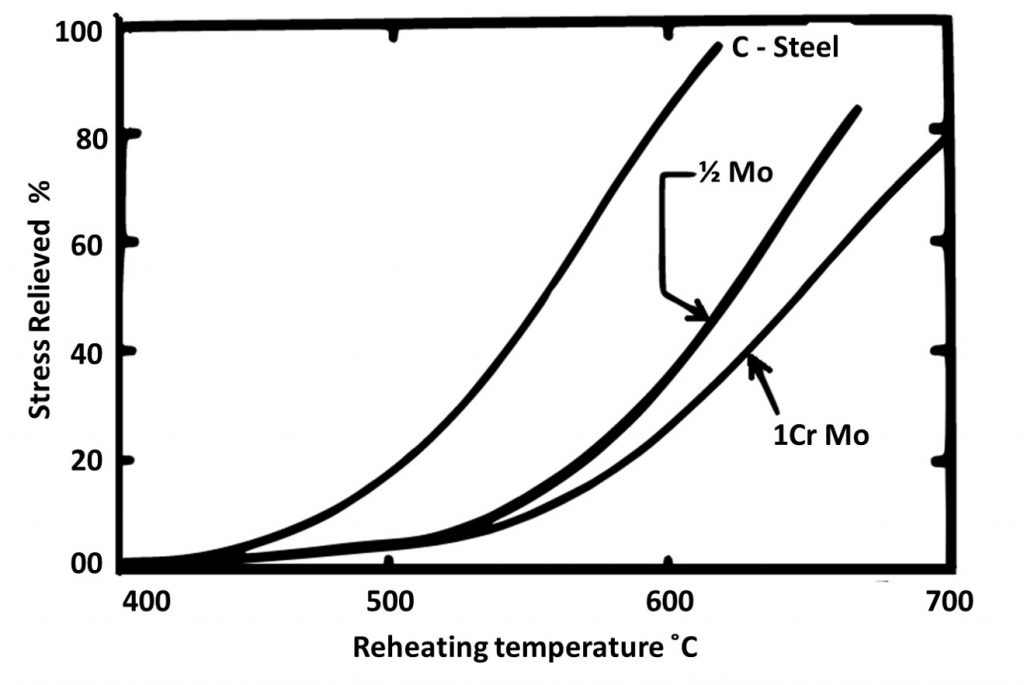

This is the stress relief process, which is named after the fact that it is carried out at temperatures where the yield strength has dropped to a low value. The yield strength of the material around the weld is unable to withstand the initial level of residual stresses, which are eased by plastic deformation, if the structure is heated uniformly. Creep occurs at high temperatures, and strain happens through a diffusion mechanism, allowing residual strains to relax even further. The extent to which residual stresses are relaxed depends on temperature and time for any given material and on material for any given temperature, see Fig. 1. A common guideline on time for post-weld heat treatment is that the joint should be soaked at peak temperature for a period of 1 hour for each 25 mm (1 inch) of thickness.

At higher temperatures, the stress distribution becomes more uniform, and stress falls to a low level. The better stress distribution is retained after cooling, as long as it is done in a controlled manner.

Stabilize and Reform the structure

Post-weld heat treatments at higher temperatures allow for certain tempering or ageing effects in addition for the reduction and re-distribution of residual stresses. These metallurgical alterations are usually helpful because they diminish the high hardness of the as-welded structures, impart ductility and lowering the danger of brittle fracture. In some steels, ageing/precipitation may cause toughness and ductility to deteriorate, therefore care should be taken on times and temperatures for different steels.

In Summary, Why Post Weld Heat Treatment PWHT?

- Welded joints retain internal stresses within the structure

- HAZ of welds remains invariably hardened

- Post Weld Heat Treatment relieves these internal stresses and softens HAZ. This reduces the chances of the cracking of the equipment which is in service

As can be seen from the previous description, different PWHTs are necessary depending on the material of the structure or component in consideration in order to achieve the proper quality weld. The following are some of the most common PWHT processes utilised in the fabrication sector.

- Annealing,

- Sub-critical annealing,

- Normalizing,

- Stress relieving,

- Quench annealing,

- Hardening and tempering.

Why Post Weld Heat Treatment PWHT has to be done within specified temperature range?

To be able to manage the metallurgical changes in a positive way, an upper limit on the soak temperature is required to avoid compromising the parent material’s mechanical properties. This demands understanding of equilibrium diagram, particularly the lower critical (Ac1) line.

Fabrication Code decides the Post Weld Heat Treatment PWHT cycle

Some fabrication standards have mandatory post-weld heat treatment for some materials, because that equipment is required to provide adequate component life in severe conditions. The alloying content of the steel is linked to post-weld heat treatment temperatures, just as it is with preheat.

Example: ASME Sec. VIII Div-1 PWHT Procedure and Requirements: UW-40, UCS-56, UHA-32, UNF-56, UHT-56 give requirements of PWHT for different P-numbers, also in some P-numbers code has also given exemption from PWHT

Learn more about PWHT code requirement here

The necessity for post-weld heat treatment depends on the material and service requirements. Other factors include welding conditions and a knowledge of types of failure.

Why Post Weld Heat Treatment PWHT should be done “only” if it is mandatory by code?

Post-weld heat treatments are more expensive than preheat and post-heat because they involve much higher temperatures. Again, usage of post-weld heat treatment should be considered only if it is required to ensure that the structure’s service performance matches the design specifications.

It is a more critical process with increased potential for detrimental effects if not carefully carried out. This necessitates careful assessment of heating rates, cooling rates, tolerances on holding temperature and holding time if benefits are to be ensured.

Features of Post Weld Heat Treatment PWHT

Aspects of post-weld heat treatment must be considered:

1. To avoid introducing additional thermally induced strains, the hot zone should be large enough to elevate the weldment to the appropriate temperature and give a consistent temperature profile. This factor is more important in localised heat treatments, but it must be considered in furnace heat treatments as well.

2. the heating and cooling rates should meet the essential code requirements.

3. The temperature gradients away from the hot zone should not be excessively harsh in localised heat treatment. British Standards BS5500 and BS2633 have the 2.5√Rt rule. ASME Sec. VIII also has local heating guidelines for soak bands, heating bands and gradient control band.

4. For the required time given by code, the soak temperatures should be kept between the high and lower limits of the soak range.

5. The energy input and level of control for the heat treatment system (including insulation), zonal division, and number of thermocouples should be proper so that PWHT objectives are fulfilled.

References

- D Croft, “Heat Treatment of Welded Steel Structures”, Woodhead Publishing in welding, Elsevier, 1996

- Parmar R S, “Welding Engineering and Technology”, Khanna Publishers 2004