Electrostatic precipitator (ESP)

It is an electrical device to precipitate suspended fly ash and dust particles from the flue gas by ionizing the particles in an electric field and collecting them subsequently on oppositely charged electric plates. It was first introduced by Dr. E G. Cottel in 1906 and was first economically used in 1937 for the removal of dust and ash particles carried with the exhaust gases of the thermal power plant.

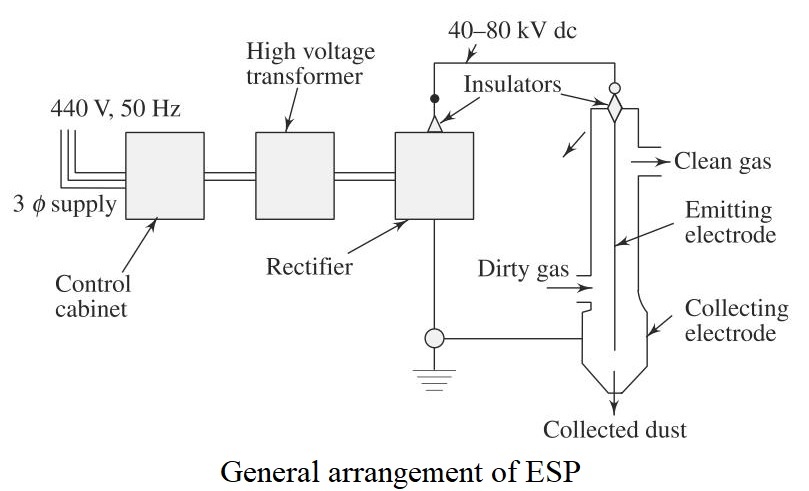

The components of ESP are…

- High voltage source (440V 50Hz 3phase supply)

- Ionizing and collecting electrodes

- High voltage transformer

- Rectifier to convert AC into DC.

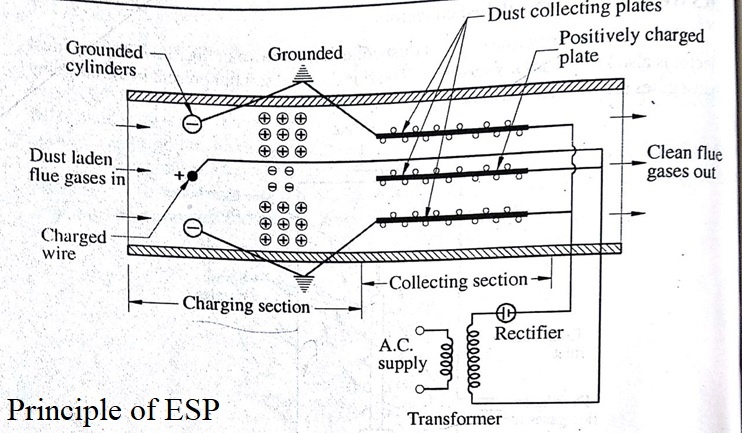

The two sets of electrodes (ionizing and collecting) are insulated from each other. The first set consists of rows of electrically grounded vertical parallel plates, called the collection electrodes. The second set of electrodes is composed of wires, called the discharge or mitting electrodes that are centrally located. The emitting electrodes (wires) carry omnidirectional positively charged high-voltage (between 30 to 100kV) current from an external DC source.

When the dust laden gas is passed between charged wires and grounded cylinders this gas becomes ionised as the voltage applied between the electrodes is as high as 30,000 to 100,000 V. The magnitude of applied voltage is dependent on electrode spacing. As the dust laden gas is passed through these highly charged electrodes, both negative and positive ions are formed, the latter being as high as 80%. When the charged dust particles are passed between the plates (collecting electrodes), the electrostatic field exerts a force on positively charged dust particles and drives them towards the grounded plates (collecting electrodes). Negatively charged dust particles attract towards the positively charged plate. The deposited dust particles are removed from the plates by giving the vibration knocks to the plates with the help of cams driven by extremal means. The removed dust from the plates is collected in the dust hoppers.

If the size of dust particles is high, ESP is used in combination with cyclone separator. The ESP has a high collection efficiency of the order of 90% and above. The electrostatic precipitators are extensively used for removing fly ash from flue gas in coal fired thermal power plants.

Advantages of electrostatic precipitator (ESP):

(1) It is the most effective method to remove very fine particulates, as fine as 0.01μm, which escape removal by mechanical separators.

(2) It is very useful for high dust loaded gas. Flue gas containing dust particles as high as 100 g/m3 can be effectively cleaned.

(3) Dust removal efficiency is as high as 99.5%.

(4) Its operation is easy and smooth.

(5) The draught loss (pressure loss) is minimum.

(6) It can remove both wet and dry dust.

Disadvantages of electrostatic precipitator (ESP):

(1) Its capital cost is high.

(2) The running charges are high as the amount of power required for charging is considerably large.

(3) Its removal efficiency drops with the increase of gas velocity.

(4) It requires more floor space.

Q1. Explain principle and working of electro static precipitator(ESP).