Function of air preheater function:

The air preheaters are employed to recover the heat from the flue gases and this heat is utilized to increase the temperature of air before it supply to the furnace.

An air preheater is placed between the economizer and the chimney and it extracts heat from the flue gases and transfers to air which is entering the furnace. The portion of the heat that otherwise would pass up the chimney to waste.

Advantage of pre-heating the air:

(1) It increases the temperature of the furnace gases, improves combustion rates and combustion efficiency.

(2) Air preheater extracts heat from the flue gases, and lowers stack temperatures thus improving the overall efficiency of the boiler. It has found that a drop of 20-22˚ C in the flue gases temperature increases boiler efficiency by 1%.

(3) The preheating air facilitates the burning of poor grades of fuel thus permitting a reduction in excess air.

(4) It increases steam generating capacity per unit m? of boiler surface.

(5) Increased thermal efficiency of plant and saving of fuel.

(6) In case of pulverized coal combustion hot air can be used to dry coal, to transport pulverized coal to burners and to accelerate combustion.

Types of air preheaters:

(1) Recuperative type : i) Plate type (ii) Tubular type

(2) Regenerative type

(1) Recuperative type air preheaters

In recuperative type of air preheaters, the two fluids (air and flue gases) are separated oy neat transfer surface, one fluid (air) flowing constantly on one side and other fluid (flue gases) on other side of the surface.

Recuperative type of air preheater is further classified as tubular type and plate type.

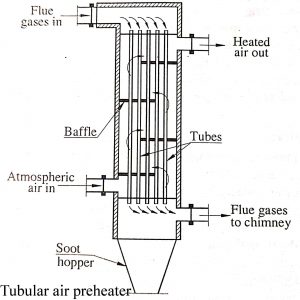

(i)Tubular air preheater:

It consists of a large number of tubes rolled into sheets as shown in figure. The flue gases flow through tubes and air is passed over the outer surface of tubes in a direction opposite to that of flue gases flow. The heat transfer takes place from flue gases to air to be supplied to the furnace. The horizontal baffles are provided to increase Contact which will help for higher heat transfer. A Soot hopper is lifted to the bottom of casing to collect soot. The diameter and height of tubes are commonly used for 6 to 8 cm and 3 to 10 m respectively.

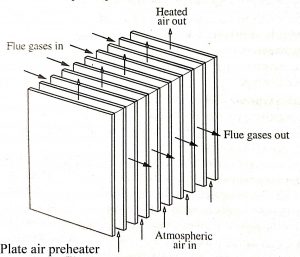

(ii)Plate type air preheater:

It consists of rectangular flat plates spaced from 1.25 cm to 25 cm apart formed alternate flue gases and air passages as shown in Fig. This type of air preheater is more expensive for installation and maintenance compared to tubular type, hence it is not used in modern power plants.

(2) Regenerative air preheaters

Regenerative type air preheater has a energy storage medium called the matrix which is alternately exposed to the hot and cold fluids. When the hot flue gases flow through the matrix in the first half of the cycle the matrix gets heated and the flue gases cooled. In the next half of the cycle when air flows through the matrix air gets heated and matrix is cooled. The cycle is repeated. The heat transfer from flue gases to air is thus periodic, There are two types of regenerative air preheaters as stationary regenerative air preheater and rotary regenerative air preheater.

A rotary regenerative air preheater is shown in Fig. called Ljungstrom air preheater, which consists of a rotor driven by an electric motor. The rotor divided into a number of sectors (12 to 24 sectors), each sector being fixed with steel sheets, either flat or corrugated. These sheets form the heat transfer surfaces. The rotor is placed in a drum which has been divided into two compartments, air and flue gases compartments. To avoid leakage from one compartment to the other seals are provided. The rotor rotates at a very slow speed of 3-4rpm. As the rotor rotates, it alternately passes through flue gases and air zones. The rotor sheets are heated by the flue gases in their zone and transfer this heat to air when they are in air zone.

The regenerative type air preheater are compact, have less weight, occupy less space and provide enormous amount of heat transfer surface and are therefore widely used in steam power plants.

Difference between recuperative type and regenerative type air preheater

| Recuperative type air preheater | Regenerative type air preheater |

| (1) In this heat exchanger two fluids are separated by heat transfer surface. There is continuously heat transfer takes place (2) Static construction, there is only nominal leakage through joints. (3) It requires mare space compared to regenerative type air preheater (4) Less pressure drops for both air and flue gases (5) It does not required power since there is no any rotating parts. (6) The cleaning the surface is difficult. (7) It becomes very large as boiler capacity increases. Hence, for large power plant large size air preheater required. (8) For large power plant comparatively more investment and operating cost. (9) Scale depositions reduces heat transfer and effectiveness of air preheaters | (1) In this heat exchanger cold fluid and hot fluid alternately occupy same surface. There is discontinuously heat transfer takes place. First half time of cycle Surface heated by gas and remain halt cycle same surface cooled by air. (2) Heat transfer surfaces are rotated, hence leakage through sealing arrangement at the moving surfaces is high. (3) Large heat transfer surfaces being accommodated in a small volume. Hence it is very compact air preheater. (4) Large pressure drops for both air and flue gases. (5) It needs power to rotate the matrix rotor. (6) The cleaning the surface is not difficult. (7) It is very economically used for high capacity boilers and plants. (8) For large power plant comparatively minimum initial and operating costs. (9) Scale deposition does not reduce the heat transfer. |

Q1. How does air preheating save fuel in steam power plant?

Q2. Compare regenerative and recuperator type of air preheater

Q3. Classify air preheaters. Describe them in brief.